Behind the scenes: Clipper 70 fleet refit

26 August 2022

After completing the twelfth edition of the Clipper Round the World Yacht Race, the eleven-strong fleet of Clipper 70 racing yachts are finally back at HQ in Portsmouth Harbour, UK ready for refit.

During the 2019-20 edition, the identical 70ft yachts raced over 40,000 nautical miles though some of the most inhospitable stretches of the world’s oceans, withstanding both extreme heat and freezing temperatures. Now back at base, they will undergo an extensive decommissioning, refitting and commissioning process ahead of the Clipper 2023-24 Race.

No stone is left unturned during the Clipper Race refit. It takes the 20-strong team of both dedicated refit and Clipper Race maintenance staff approximately 35,000 work hours to strip out, lift, inspect, maintain, clean, and, where necessary, repair or replace parts or fittings.

AQP of Zhuhai, James Finney, climbs the mast during the Clipper 2019-20 Race

Justin ‘Jay’ Haller, Chief Engineer, has been with the Clipper Race for 20 years. He has worked on every generation of Clipper Race ocean racing yachts and oversees the mammoth refit operation. Jay said: “These boats are over-specced compared to what you’d see on a regular yacht. Everything down to the thickness of the hull is over-specced. So although I’m not surprised, I'm pleased to see that the boats have held up really, really well. I have no qualms about them doing another race. There are some cosmetic repairs, naturally, but that’s to be expected.

Rigger Andy Peck dissembles a Clipper 70 mast

“The boats come out of the water for 36 days and we work on them two at a time. After the masts are removed, one of the first jobs we do is take the generators and main engines out to work on them in the yard.”Martyn Read and Dan Jones remove an engine through the deck hatch.

The first yachts to be lifted are CV20 (Imagine your Korea) and CV22 (Seattle). Former WTC Logistics Race Skipper Dan Jones is part of the refit team and has been overseeing the first engine lift. He explains: “ When we lift the engines, we have to disconnect the gear box and the shaft to the propeller. We then have to disconnect the fuel lines and the water pipes, battery cables, alternators, mounts and then the actual engine mount.

The engine is lifted from CV22 during refit

“We can lift the engine through the hatch on deck and then lower it to the hanger floor so that we can sandblast the brackets, replace the mounts, remove and service the raw water pumps, remove the alternators to send them away for a strip and service. Once it’s out it's much easier to do that way.”

Scheduling the work is a task in itself to ensure the yachts are ready in time for the next intake of training and to fulfil Clipper Events sailing commitments. The workload is extensive, as Jay explains: “Each boat is stripped, sanded and painted in the interior. Once painted, we replace all the piping - saltwater, freshwater, all of it as a matter of course. The floorboards are then inspected and if any are damaged they will either be sanded down, repainted and covered with kiwi grip - or replaced if necessary. The gas infrastructure is replaced as a matter of course.

“Each yacht’s wiring gets inspected and replaced, then all the standing rigging is stripped off and replaced. At this point, we often get the team at Sta-Lok to take a look at the fittings that have come off so they can see how well it has stood up against the elements and for future product development. The masts are inspected and stress tested where necessary.

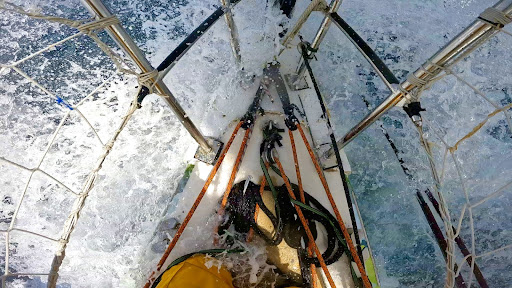

Big splash on the bow of a Clipper 70

“We have had surveyors down who confirmed that there’s nothing major we need to do. However we will still remove the keel bolts and inspect them as a matter of course to see if there is any corrosion on the keel and to check the bolts themselves.”

Whilst safety absolutely comes first, the refit is carried out with sustainability in mind. Jay explains: “Our aim is to repurpose as much as possible but if there's any sign of potential damage - or a health or safety issue - then we absolutely replace the part or fitting.”

For the first time, thanks to the Coppercoat covering, the Clipper Race fleet doesn't need antifouling - saving time and reducing the refit’s carbon footprint with the environmentally responsible coating. Jay said: “The Coppercoat has lasted REALLY well! Each of the hulls will have a light sand.

“We had a rudder for one of the boats rebuilt in Cape Town which we didn't have time to Coppercoat, so we had to use regular antifoul on it. It’s a stark comparison, it has about half an inch of growth on it, whereas the rest of the boat had Coppercoat, including the yacht's other rudder and it was as good as new with just a simple pressure wash.”

Coppercoat on the hull of GoToBermuda

The refit also offers Jay and his team the chance to update, upgrade or make changes to improve performance, comfort or the sailing experience for future race crews. Once back in the water, each yacht has its mast, which has also undergone full inspection and had each wire replaced, restepped and is rigged with a whopping 1,439m (excluding spares) of Marlow Ropes lines.

There’s no rest for the refit team, which is split up to tag team the conveyor belt process of each stage of the refit. Jay says: “A week before the pair of yachts are ready to go back in the water, we begin decommissioning the next pair of yachts - so everything comes off and goes into a container, and then will swap over with the current two yachts which be recommissioned and ready to go.”

Once the yachts are back in the water, the refit team thoroughly tests the systems before they are used again. But even when the entire fleet has been through refit, and systems are checked, the inspections don’t stop. Jay explains: “The fleet is Cat2 registered - for UK inshore and coastal sailing - until Race Start. Then before the race they have the CAT0 survey which is another in depth survey.”

The Clipper Race refit is a demanding operation, but one which gives the team a lot of satisfaction. Jay adds: “Being part of the refit team is a great job opportunity for anyone wanting to learn about yachts - but also those interested in engines, electrics, and anything hands on. Some refit staff end up working full time for us, too.”

Inspired to find out more about working as part of the Refit Team on the Clipper 70s? The Clipper Race is looking to expand its refit team, and is hiring refit staff to help ensure the fleet is race ready ahead of the 2023-24 edition. Find out more via the Clipper Race careers page.

https://www.clipperroundtheworld.com/jobs

Join The Race